Продукция

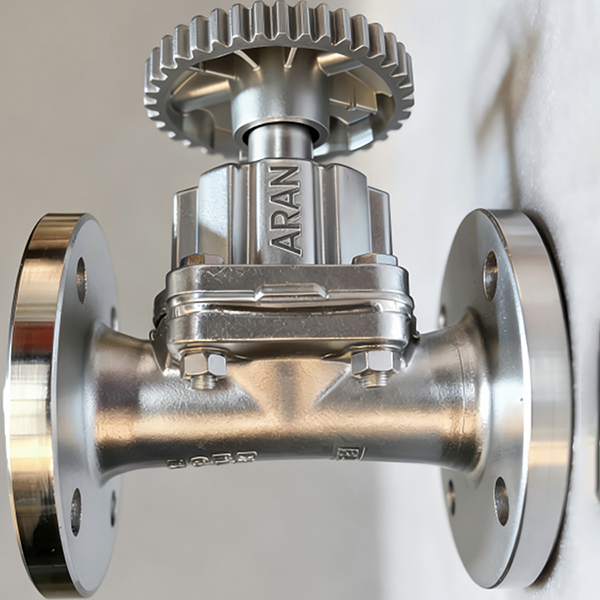

Титановый затвор кланан

Материал: Титан

Давление: Класс ASME 150~ 600 фунтов (PN16~PN 63 )

Размер: NPS 2″~ 48 ” (50 мм~ 1200 мм)

Связь: РФ, РТЖ, ЧБ

Операция: Рычаг , коробка передач, пневматический, электрический

Описание

маркер

Введение в продукт

| Material: | Titanium |

| Pressure: | ASME Class150~600LBS (PN16~PN63) |

| Size: | NPS 2”~48” (50mm~1200mm) |

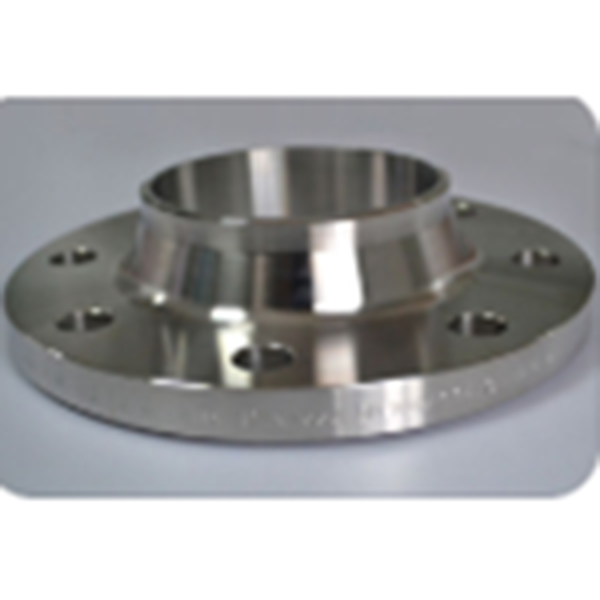

| Connection: | RF, RTJ, BW |

| Operation: | Lever, Gearbox, Pneumatic, Electric |

Key Performance Characteristics

1.Corrosion Resistance

Passivation Layer Protection : A dense titanium oxide (TiO₂) film naturally forms on the surface, providing exceptional stability in oxidizing media (e.g., chlorine water, sodium hypochlorite, wet chlorine gas, nitric acid). Resistance to reducing acids can be enhanced via inhibitors or surface treatment.

Special Media Compatibility : Resists aqua regia, chlorides, seawater, alkalis, and strong corrosive environments like hydrochloric and phosphoric acids.

2.Structural Design

Triple Offset Sealing: Zero friction between disc and seat during operation achieves "tightening when closing" zero leakage performance, extending service life by >30%.

Lightweight & High Strength : 50% lighter than equivalent stainless steel valves. Streamlined truss structured disc ensures high strength and low flow resistance (pressure loss ≈ 1/3 of gate valves).

3.Physical Properties

Temperature Range: 30°C to 315°C (short term tolerance for cryogenic/steam exposure).

Actuation Compatibility: Supports worm gear, electric, pneumatic, and hydraulic drives. ISO compliant brackets enable automation integration.

Typical Operating Conditions

| Condition Type | Strong Oxidizing Media | Technical Highlights

|

| Seawater/Brine Systems | Wet Cl₂, NaClO, concentrated HNO₃ | Relies on Ti passivation; prevents metal ion contamination

Seawater, chlorinated cooling water |

| Reducing Acid Environments | Dilute HCl, H₃PO₄, organic acids | ideal for desalination/ship pipelines

Requires inhibitors or modified Ti alloys (e.g., TA10)

|

| High Temp/Cryogenic Media | Steam (≤315°C), LN₂ (≥ 30°C) | Metal sealed structure withstands thermal shock

|

Primary Applications

1.Chemical & Energy Industries

Chlor Alkali/Soda Ash: Cl₂ transfer, electrolyte pipelines (replaces graphite valves).

Acid Production: SO₂ control in sulfur furnaces, converters, drying towers (high temp corrosion resistance).

Nuclear/Desalination: Seawater cooling circuits (salt mist immunity).

2.Environmental & Metallurgy

Wastewater Treatment: Shutoff for chlorinated/acidic effluents (PTFE/graphite seals optional).

Hydrometallurgy: Acid leaching solutions (e.g., TiO₂ production).

3.Advanced Manufacturing & Civil Sectors

Food/Pharma: Sanitary grade valves (TA2/TA10), FDA compliant for sterile processes.

Marine Engineering : Ballast water systems, coastal power plant seawater pumps.

Critical Selection Factors

Material Compatibility:

Body/Disc: TA1 (commercially pure Ti) for general corrosion; TA10 (Ti 0.3Mo 0.8Ni) for crevice corrosion; TC4 (Ti 6Al 4V) for high strength stems.

Sealing Systems: Ti + flexible graphite for high temp; Ti + PTFE for cryogenic/acidic media.

Pressure Design:

Bidirectional pressure rating (PN2.5–PN100); hardened sealing surfaces (e.g., Co based alloy overlay) for high pressure duties.

Summary

Titanium butterfly valves are technologically essential for highly corrosive, wide temperature, and weight sensitive applications. They are irreplaceable in chlor alkali, seawater, and high purity industries. Selection must prioritize matching media redox properties with Ti grades and adopt triple offset designs to optimize sealing longevity and throttling precision.